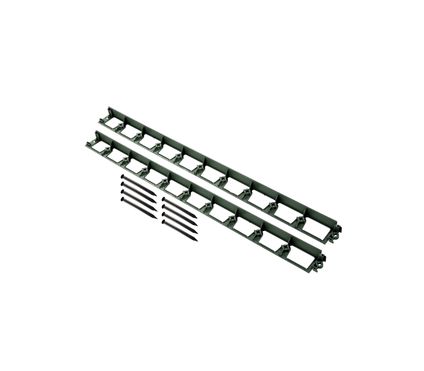

Delima Green Flexible Border Edging Strip

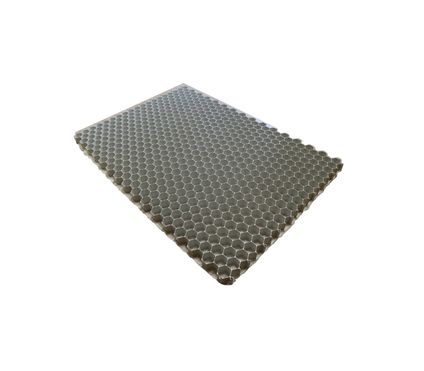

Integrated 60g/m2 geotextile membrane permanently attached to the module.

Integral interlocking assembly system to ensure maximum stability of adjoining modules.

Honeycomb cells.

Aggregate stabilisation module with integrated geotextile membrane for use in landscaping projects. Ideal for creating walkways, garden paths, car parking areas, paths and driveways for private, public, commercial or industrial use. Creates a perfect finish, because the module becomes invisible when filled.

Alveplac® is guaranteed effective once the modules have been filled with aggregate, plus an additional 2 cm top layer (the aggregate may need to be raked from time to time). Our recommendation is to fill the honeycomb tiles with crushed 5/15 or 8/16 aggregate graded to between 5 mm (min.) and 16 mm (max.).

Compatible with IHBOUCALVBS10000 & IHBOUCALVGS10000 zone markers. Allow 2.2 zone markers per linear metre. Actual quantities will be determined by the project and its environment.

For heavy traffic, use our URBANGRAVEL ref. Do not use with hot asphalt. Visit our website for installation advice.

Stabilises aggregate surfaces. Consolidates aggregate surfaces used by vehicles, and to create garden paths, car parks, terraces, paths and other pedestrian areas for private, public, community, commercial or industrial use and for emergency vehicle access. Facilitates use by cyclists, parents with pushchairs, etc. Creates a perfect finish, because the module becomes invisible when filled. For outdoor use.

The geotextile membrane separates the distinct sub-layers of the soil. This makes it possible to separate sand from aggregate, for example. The geotextile membrane also prevents weeds from growing in the gaps between the gravel.

The use of an aggregate stabilisation module is essential to avoid the creation of ruts by repeated use of vehicles entering and leaving a garage, for example.

We recommend the addition of a 2 cm top layer of 5/15 or 8/16 driveable aggregate to ensure that all the cells are completely filled. Once the aggregate has been poured into the stabilisation module, it should no longer be possible to see the module itself.

of existence at your service

to bad weather

and environmentally friendly

thanks to our innovative systems

Jouplast® guides you in your outdoor development project (terrace, staircase, driveway) by establishing a complete shopping list in 5 minutes.

Also benefit from expert advice to install your project with complete peace of mind.

You will find here all our directions for use.

Find the point of sale closest to you using our dealer map. We remind you that no products are sold directly. Please contact one of our distributors if you wish to receive a quote or make a purchase.

Our products are installed by numerous landscapers or public works companies. We encourage you to contact one of these professionals for the installation of Jouplast® products.

If you need assistance or information, you can reach out to your distributor.

Thank you!

To find the price of your Jouplast® product, we invite you to contact your nearest distributor.

We do not sell directly to individuals or professionals.

To find a price, we recommend contacting your usual distributor.

If your product is defective, we invite you to contact your distributor.

If the response from your distributor is not satisfactory, please feel free to write to us using the contact form.

In the case of receiving slightly deformed or warped pads, we assure you that they remain suitable for installation. Once the covering is installed, the pad will return to its original shape.